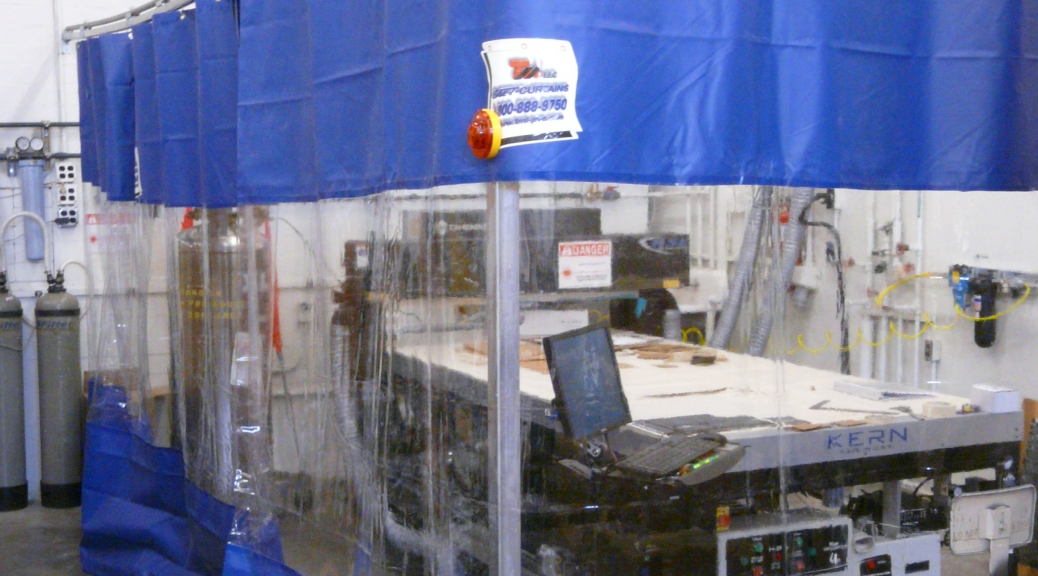

After becoming aware of unique fabrication needs within our group and other groups on campus, I initiated, wrote, and managed a successful grant proposal for a $200k high-power laser cutter system and have since been responsible for installing and managing the system. The system is a Kern HSE 100 with 400W laser and metal-cutting and rotary stage add-ons. (The rotary stage was developed at our request.)

Although this system has been great for cutting a variety of materials, it isn’t ideal for making precise cuts in thin foils, and disappointingly was not suitable for ablating the copper from PCB material for making circuit boards. More recently, I submitted a successful proposal for an $230k LPKF ProtoLaser U3 micromachining and PCB prototyping system, which will be delivered to the lab in September 2014.